Fujitsu announced that it has developed a new system based on Fujitsu Data Intelligence PaaS an operation platform for Fujitsu Uvance that leverages data and AI to achieve resilient supply chain management for Electric Works Company, Panasonic Corporation (Panasonic EW), and has started a full-scale operation of the new system at Panasonic EW in April 2024.

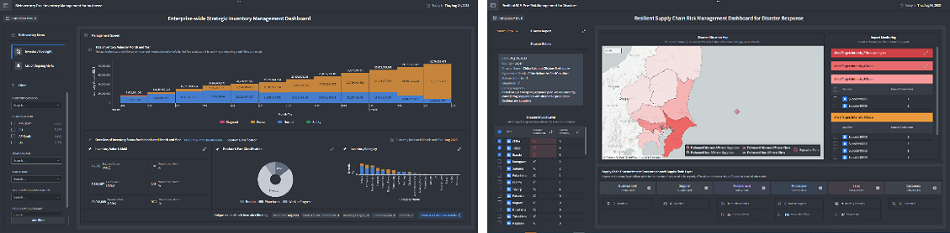

The new system will integrate large amounts of data residing in more than 3000 sites, including domestic and overseas suppliers and factories across the entire organization to support decision making for business continuity. Panasonic EW, which handles electrical construction materials, manages tens of thousands of products, parts, and other information for each department, division, and location separately, using different formats of data. The introduction of the new system manages the data integration of 20 existing systems, including production, sales, inventory, and parts procurement, as well as the identification and visualization of parts with more than 200,000 parts in stock. This has resulted in increased optimization of the PSI plan and parts procurement plans at company-wide level. In addition, it also leverages the use of AI to implement accurate demand forecasting models based on data.

Panasonic EW enables dynamic and resilient supply chain management by using data to quickly respond to disasters or changes in the business environment by using AI to predict the uncertain outcomes in order to make corrective decisions.

Features of the new system

Panasonic EW utilized Fujitsu Data Intelligence PaaS to integrate, store, and visualize data, and to develop an all-in-one business system. As a result, it has been able to gain control of PSI information, parts procurement plans, and inventory status at each site at the company-wide level, thereby improving efficiency promoting operations across divisions, and achieving inventory leveling by adjusting inventory among sites and suppressing orders. Furthermore, the new system will give insight on each order received during natural disasters, as well as the impact of profit and loss on the entire business and will ultimately support decision-making for maintaining production and supply systems.

In addition, by leveraging Fujitsu Data Intelligence PaaS's seamless data integration capabilities, Panasonic EW successfully identified and visualized parts in its inventory of over 200,000 parts in as little as 2 weeks, without the modification of existing systems.

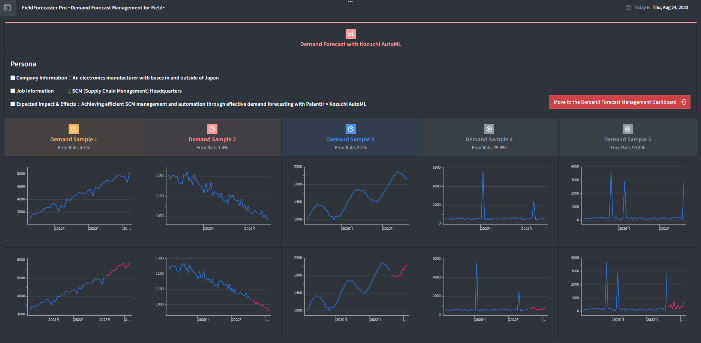

Formulating high-precision demand forecasts with AI

Panasonic EW utilized Fujitsu Kozuchi AutoML, Fujitsu’s AI service that can generate highly accurate machine learning models in a short period of time, to generate 300 predictive models based on sales results of key components over the past 5 years from information integrated into the data base. This will enable highly accurate PSI planning for each component category.

Future Plans

Towards 2030, when the labor shortage is expected to become apparent due to the rapid decline in the working-age population in Japan, Fujitsu will support Panasonic EW in building a sustainable and resilient supply chain system and promote operational reforms to achieve high productivity that will allow them to complete similar tasks with 50% of their current man-hours.

Under Fujitsu Uvance, Fujitsu will contribute to the realization of a sustainable world by providing a comprehensive view of the entire supply chain through Digital Shifts initiatives that utilize data and technology to help companies strengthen their resilience and respond to environmental and societal issues.

-

[1]Fujitsu Data Intelligence PaaS :

Platform consisting of Fujitsu Kozuchi, a cloud-based AI service, Fujitsu Track and Trust, a blockchain technology that enables data linkage and traceability across companies and industries, Palantir and Microsoft Azure -

[2]PSI plan :

Acronym for Production, Sales, and Inventory, and refers to planning all three simultaneously -

[3]Applications built on Palantir

Related Links

Fujitsu’s Commitment to the Sustainable Development Goals (SDGs)

The Sustainable Development Goals (SDGs) adopted by the United Nations in 2015 represent a set of common goals to be achieved worldwide by 2030.

Fujitsu’s purpose — “to make the world more sustainable by building trust in society through innovation” — is a promise to contribute to the vision of a better future empowered by the SDGs.

The goals most relevant to this project

About Fujitsu

Fujitsu’s purpose is to make the world more sustainable by building trust in society through innovation. As the digital transformation partner of choice for customers in over 100 countries, our 124,000 employees work to resolve some of the greatest challenges facing humanity. Our range of services and solutions draw on five key technologies: Computing, Networks, AI, Data & Security, and Converging Technologies, which we bring together to deliver sustainability transformation. Fujitsu Limited (TSE:6702) reported consolidated revenues of 3.7 trillion yen (US$26 billion) for the fiscal year ended March 31, 2024 and remains the top digital services company in Japan by market share. Find out more: www.fujitsu.com.

Press Contacts

Fujitsu Limited

Public and Investor Relations Division

Inquiries

All company or product names mentioned herein are trademarks or registered trademarks of their respective owners. Information provided in this press release is accurate at time of publication and is subject to change without advance notice.

Date: 29 May, 2024

City: Kawasaki, Japan

Company: Fujitsu Limited