Cart

0

For all AOI programmers out there, we understand false calls can be tricky to manage. What’s the root of your false calls? This is the question that might haunt your dreams… Therefore, knowing precisely where to analyze false calls can make a tremendous difference in your day-to-day job. And we have something to help you with that.

In this short article, we’ll show you how to optimize your inspection performance using an SMT analytics tool with an option to drill down into false calls. In this case, we’ve used Cogiscan’s Factory Intelligence, which offers in-depth analysis for AOI and SPI (Solder Paste Inspection) machines.

Reducing False Calls Through Analytics

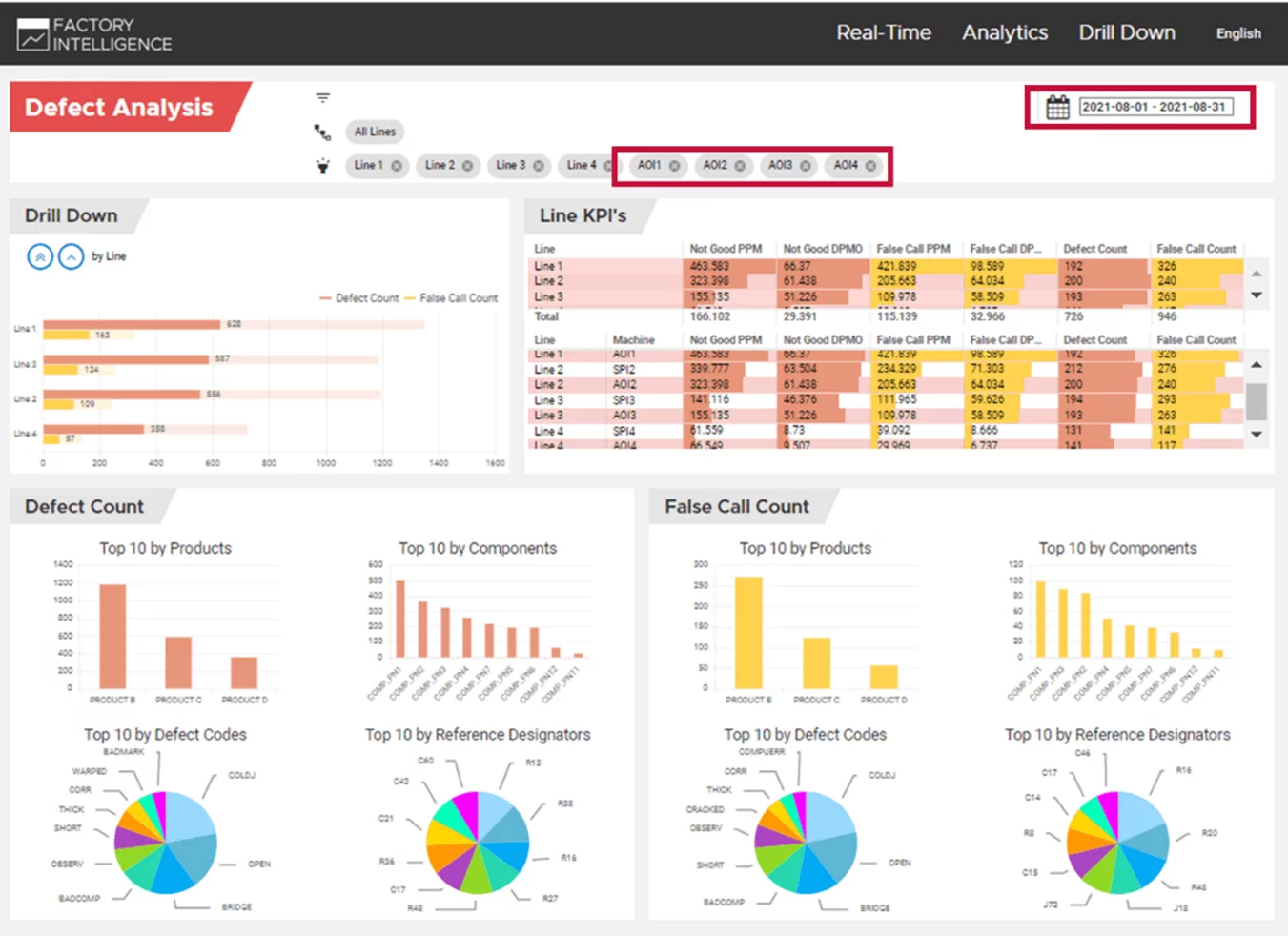

As we’ve already said, False Calls are a huge pain for most AOI operators. As an example, let’s look at a fictional SMT factory’s false calls for the last month. In order to do that, we’re going to open Factory Intelligence, select the appropriate timeframe, and then click on all lines’ AOIs to capture all the false calls that happened.

After doing that, we’re going to look at the Top 10 Components with the most False Calls. As shown in the screenshot below, we’ve got some outliers: COMP_PN1, COMP_PN2 and COMP_PN3 have almost double the number of False Calls.

Again, we’re going to drill down on those components by clicking on them. By looking at the top left, we can see (in yellow) the percentage of our False Calls these 3 components are making up (in both cases, over 50% of the false calls on each respective line: 163/250 for LINE #1 and 109/220 for LINE #2).

Looking at the bottom right, we can analyze the defect codes for these components. In this case, most of our False Calls were for: cold solder joint, open solder joint and bridging.

Based on this pareto analysis the AOI technician can now proceed to adjust the inspection program while focusing on reducing false calls for these specific components and associated defect types. This data-driven and focused approach assures that changes to the inspection program will yield the largest return on effort possible.

And meanwhile, by looking at the bottom left of the Factory Intelligence screen, we can see that those same three components are also our main culprits for REAL defects. This serves as an important and helpful reminder for the AOI technician to be very careful while adjusting the AOI program (aoi production control planner)… since no one wants to create escape problems while trying to reduce false calls.

And meanwhile, by looking at the bottom left of the Factory Intelligence screen, we can see that those same three components are also our main culprits for REAL defects. This serves as an important and helpful reminder for the AOI technician to be very careful while adjusting the AOI program (aoi production control planner)… since no one wants to create escape problems while trying to reduce false calls.

Conclusion

This is only one way of reducing your factory’s false calls. However, Factory Intelligence offers so much more than that. For example, it can also help you reduce your mispick rate for placement machines, therefore increasing your overall line performance. It can also help you with your factory’s OEE. Contact one of our experts today to know how the right tool could help you!